With extensive combined knowledge and experience, we understand the regulated specification standards and technical requirements to achieve finished surfaces across many industries. Contamination in the processing of ingestible and injectable pharmaceuticals can have devastating consequences. That is why it is so critically important to produce and finish stainless steel equipment and components to exacting standards.

The equipment used in processing environments is susceptible to rouging and contamination, thus must be produced and finished in a way that makes it easy to clean and sanitize.

For original equipment manufacturers, the intricacies involved with the manufacturing and fabrication of sanitary stainless steel equipment require a team of engineers, welders and polishers with industry-specific knowledge and expertise. Engineers must understand and apply the various regulations for the equipment’s contact and non-contact surfaces. The equipment fabrication process begins with selecting and proper handling of the metal. There are many stainless steel alloys, with varying degrees of corrosion resistance, magnetism and machinability. Protective surfaces and careful handling are essential when working with stainless steel for sanitary applications to prevent contamination from the manufacturing environment throughout all processes.

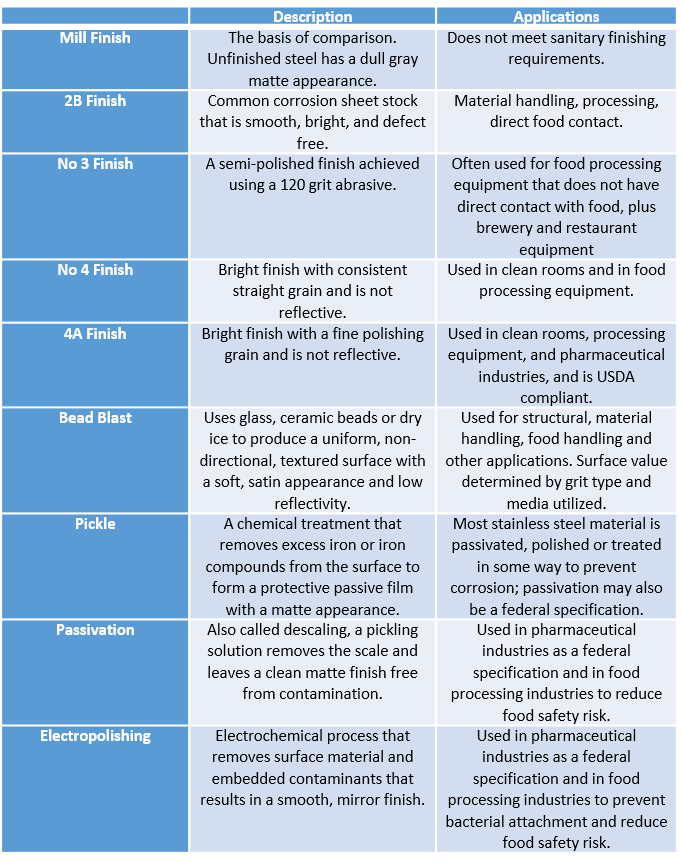

Today, there are many surface finish options for stainless steel vessels, fittings, tubing, valves and other processing components. Food, beverage, pharmaceutical, personal care and other processing industries require specific finishing standards for sanitary conditions that are regulated by government agencies. And what is defined as hygienic or sanitary can differ by industry.

When we talk about a sanitary surface finish, we are referring to the surface’s roughness, which is one element of its overall texture. Stainless steel equipment requires a sanitary finish meaning that it is smooth, scratch-free, and corrosion-resistant.

Mechanical and Chemical Methods of Finishing Stainless Steel

There are several mechanical and chemical finishes that can achieve various industry specifications. To determine an appropriate finish, it is important to understand some key terminology and related information. Surface texture characterizes the material’s surface based on irregularities and deviations, and roughness and grain.

Grit is the size of the abrasive used in the polishing process. Lower grit numbers are coarser and associated with grinding, and higher grit numbers are associated with polishing.

Measured in microinches or micrometers, the surface’s roughness average (Ra) is a standard specification that calculates the smoothness as an arithmetic average of the microscopic peaks and valleys across the metal’s surface. A profilometer is a tool used to measure the surface topography, including roughness, profile/dimension, flatness, volume, and step height.

Smooth, crevice and pit free surfaces with low Ra readings ensure there are no entrapment areas on the product that can be difficult to clean and allow bacteria to accumulate.

Mechanical and chemical are the two methods for achieving a surface finish for high purity applications. Mechanical polishing removes material using an abrasive with a grit size of 120 or finer. Chemical surface treatments remove the outer layer of corrosion on the material to maintain the metal’s purity.

Finishing Stainless Steel for Appearance and Texture

AMF Technologies provides comprehensive metal finishing services for a variety of markets including the pharmaceutical and biopharmaceutical industries. Let us know how we can help.

Contact Us if you have any questions or for more information.