Electropolishing medical devices improves safety, precision, and reliability. The manufacturing of medical devices, instruments and components is a highly regulated process that requires attention to detail and compliance with stringent regulatory standards. Used both internally as well externally, medical devices, surgical instruments, and equipment have a vital role within our healthcare system so they must be ultraclean; defect-free (no flawed parts); biocompatible without adverse effects on patients’ health. Among other safety risks are burrs and microcracks left behind after machining processes allowing possible contamination and dangers such as:

- CORROSION

- CONTAMINATION

- BIO-INCOMPATIBILITY

- IMPLANT REJECTION

- PATHOGEN SPREAD

- PREMATURE FAILURE

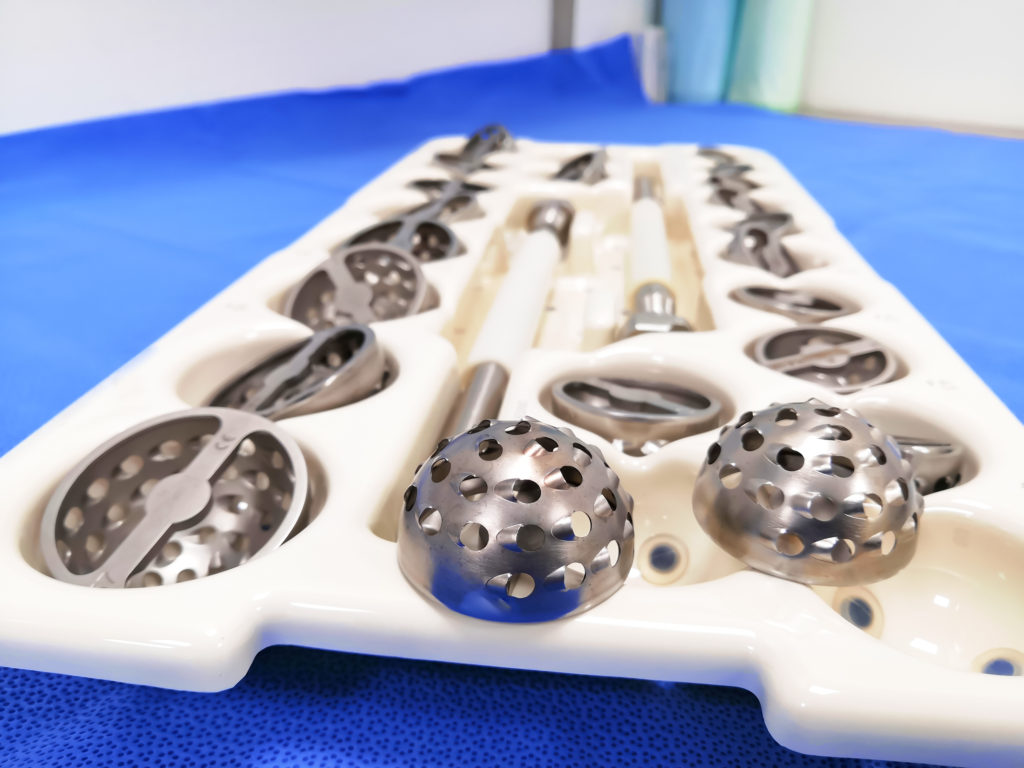

Medical device manufacturers specify electropolishing to eliminate burrs and defects by removing a microscopic layer of surface material. The finishing process also improves pathogen resistance, corrosion resistance, cleanability, and aesthetics.

The Process of Electropolishing Medical Devices

Electropolishing is often referred to as reverse plating because it removes a microscopic layer of material to eliminate surface defects. It is an electrochemical process that reduces surface roughness by leveling the peaks and valleys. It is used to polish, passivate, and deburr 200-300 series stainless steels, 300 series stainless steel, titanium, and other metal alloys.

Electropolishing uses a combination of rectified current and a blended chemical electrolyte bath to remove the metal surface flaws. The medical devices or components are immersed in a temperature-controlled chemical bath. A power source that converts AC current to DC at low voltages. The negative terminal of the DC power supply is connected to a cathode. The metal parts are positively charged (anodic) and submerged in the chemical bath. The current is applied, and the electrolyte works as a conductor to remove the metal ions from the parts. The ions are drawn toward the cathode and the electrolyte holds the dissolved metals in the solution. After the bath process, the parts go through a cleaning and drying sequence to remove any remaining electrolytes.

Expertise in Electropolishing Medical Devices

When it comes to implantable devices such as orthopedic and cardiovascular implants, and surgical instruments including cutting tools, drills and blades, precision in manufacturing and surface finishing is critical. More focus is being given to designing medical devices for pathogen resistance, corrosion resistance, and easier cleaning and sanitization with electropolishing included in the specifications.

AMF Technologies is an ISO-certified company with decades of surface finishing experience and expertise. Manufacturers trust our reliable quality and unmatched customer service. We meet and exceed the high standards set by industry organizations such as ISO, ASTM, GSA and others.

To determine if electropolishing is the right solution for your medical devices, components, or other parts, contact us or send your sample to AMF Technologies, 401 VFW Drive, Rockland, MA 02370.