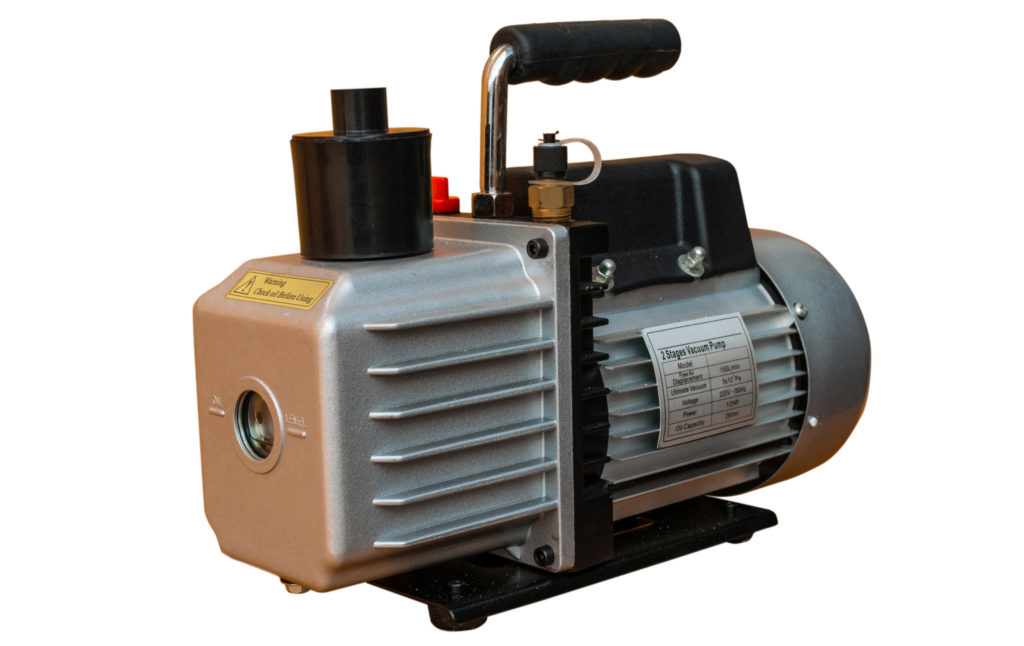

Industrial vacuum pumps are used by different industries around the world to remove molecules of air and other gases from sealed or confined spaces. Nearly every industry today requires a vacuum pump for some type of operational process. From pharmaceutical processing to electronics, pumps are crucial to manufacturing, extraction, and even medical procedures. There are many different pump technologies to support a multitude of applications.

How do vacuum pumps work?

Scroll pumps, diaphragm pumps, screw vane pumps, ion pumps, peristaltic pumps, piston pumps, dosing pumps, centrifugal pumps, and on, the types of pumps are endless.

While there are many types of pumps, they all have the same basic structure and work in the same general way. Pumps include a case or outer shell, a fluid displacement device, bearings, a hub, and the seal.

Pumps work by creating a vacuum that displaces air or other gas and produces a low-pressure area around a sealed container. There are various pump categories used for the purpose of creating a partial or high vacuum within a contained space. Using some form of power to operate, a vacuum pump takes air from the enclosed container and then discharges it. When the air pressure in the container is dropping, the partial vacuum is created. While it is not possible to remove all the gas molecules and create a complete vacuum, high-performance pumps are able to produce air pressure that is many times lower than the air outside of the container.

The three primary factors that go into pump selection include the amount of vacuum produced, the rate of air removal, and the supply of power required.

Pumps have strict tolerances and specific environments under which they must operate to generate the best efficiency point or BEP. Manufacturers calculate performance curves and provide instructions on how to accomplish BEP for each pump.

Pump Types

While classification gets complicated rather quickly, most vacuum pumps fall into one of three categories: positive displacement, momentum transfer, or entrapment.

Positive Displacement Vacuum Pumps

A positive displacement pump provides a steady, moderate flow of suction power. It produces a vacuum by confining and compressing a specific, constant amount of gas. The compressed air is vented out one opening, and a vacuum is created at the other port where the air is drawn in.

This equipment covers a wide range of low vacuum applications such as chemical, petrochemical, pharmaceutical, semi-conductor industries, and many others.

Positive displacement is a large category that is further divided into two distinct types, rotary and reciprocating. This is then divided into subcategories of many systems including piston, diaphragm, rocking-piston, rotary-vane, lobed-rotor, rotary-screw, liquid-ring and more.

Momentum Transfer Vacuum Pumps

Momentum transfer pumps, also known as kinetic and molecular pumps, are used to create powerful vacuums. They feature a rotating component which propels air or gas molecules from the vacuum side of the system to the exhaust end of the system. The molecules begin to interact more with the chamber walls than with each other since there are far fewer molecules with which to interact.

There are two primary classes of momentum transfer systems, centrifugal and regenerative, and many types.

Centrifugal pumps are widely used for applications that involve liquids and metering like food service and processing, distilleries, chemical processing, and laboratories. Very simply, they work by converting kinetic energy from a motor to force liquid to move.

Regenerative pumps are like centrifugal pumps mechanically, but they differ in that they break the pressurization process into many separate steps. They are used for low flow, high-pressure applications such as the chemical, mechanical engineering industries.

Entrapment Pumps

For ultra-high vacuums, entrapment pumps are known to be the most effective. These pumps store gas for later release using chemical reactions. The molecules in the air create a thin film which is removed by the entrapment pumps as they chemically react to the internal surfaces of the pump. It uses cold temperatures to condense gases to a solid or absorbed state. Cryopump, sputter-ion, and absorption pumps are a few sub-categories of entrapment pumps that can be found in semiconductor production, optical coatings, and medical device industries.

No matter the type of pump or category, maintaining the manufacturing equipment used in the production of your products is necessary to sustain performance. And despite your best efforts, your facility’s vacuum pumps occasionally require decontamination service.

AMF Technologies has the technical experience and equipment required to reverse signs of corrosion and properly decontaminate vacuum pumps and restore machinery to excellent working order.

Learn more about vacuum pump maintenance here or contact us for more information or to tailor a solution to your needs.